Warehouse Address

56-60 Shelley Road, Boscombe, Bournemouth,

Dorset, BH1 4HY

Main Telephone

+44 (0) 1202 309090

Email:

info@admetalspinners.co.uk

Warehouse Address

56-60 Shelley Road, Boscombe, Bournemouth,

Dorset, BH1 4HY

Main Telephone

+44 (0) 1202 309090

Email:

info@admetalspinners.co.uk

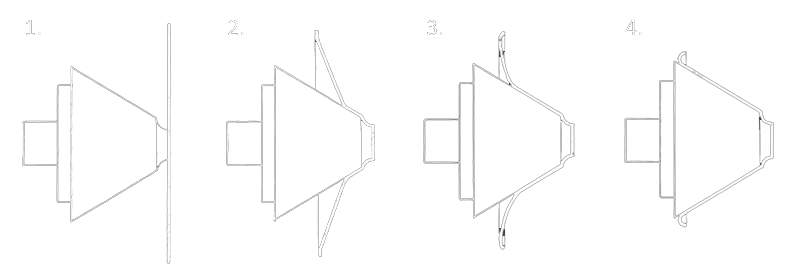

A good analogy to describe metal spinning is to compare it to using clay on a potter’s wheel. In the same way that the clay is spun and then formed to make a particular shape, metal discs are spun and formed around a tool (i.e. a shape) to form axially symmetrical parts. The spinning is the glove and the tool is the hand.

Parts are typically dished, domed, flanged, flued, hemispherical, semi-elliptical and trumpet shaped. Maybe your shape is more unique? Get in touch and we’d be happy to help with the design.

We use traditional manual hand spinning techniques alongside modern CNC methods. CNC allows us to produce high numbers with repeatable quality and this in turn allows us to achieve better economies of scale and lead times for our customers. We will develop your product from start to finish – from drawing to delivery. Whether you want a one-off or parts in the thousands, we are happy to help meet your needs

We are able to spin up to 1270mm (50”) diameter in thicknesses ranging from 0.1 to 4mm. We use standard metals such as copper, aluminium, brass and mild steel to more exotic materials typically used in the aerospace, defence and nuclear industries.

Your tools are designed using our CAD software and are made in-house by our precision tool makers. With our recent investment in a state of the art CNC turning lathe, we can guarantee the dimensions of any feature of your tool as well as having the benefit of an increased turnaround time for tool making.

Once made, you own all retention rights to them unlike other spinning shops. Power pressing, laser cutting, water-jet cutting, welding, polishing, turning and circle cutting are all services we offer.

We also have long standing relationships with heat treatment and finishing experts so all bases are covered.

Metal spinning forms conical, hemispherical and cylindrical shapes. It is a cost-effective process for producing these types of parts in low to medium quantities and has short lead times.

With large quantities, stamping may be a more cost-effective choice, however as the part diameter and tooling costs for stamping increase, metal spinning is usually a more economical choice – especially when utilising our CNC capabilities.

Metal spinning also competes favourably with a variety of plastic fabrication processes, especially where the cost of metal is often less expensive than petroleum-based material.

If you’re not sure whether your part can be made in this way, get in touch and we’d be happy to help you find out.

We have achieved certification to the highest levels of quality available; AS9100D, ISO9001 and Airbus. Having these certifications ensures that our parts suit the rigorous expectations of the Aerospace industry and beyond.

We make sure that all the parts we manufacture are inspected thoroughly. Every part is treated with the utmost care and attention and we use state of the art CMM software to make sure they adhere to the drawing.

Our spinnings have gone all over the world and indeed out of it - we even have a part on ‘Io’, a moon of Saturn!